For many makers, the creative aspects of running a small business come easy. Choosing recipe ingredients, design, color, and fragrance is fun! Selling is where it gets confusing - specifically how much to charge for each bar of soap. While there’s no black and white guide for pricing, this article can help you get started.

Before we dive in, keep in mind these numbers are very simple and meant to give you a place to start. You can adjust them to fit your needs.

Fixed Overhead Costs (Indirect Costs)

These are things like heat, electricity, phone bills, etc. If you're like many small-scale soap makers, you work out of your own home or apartment. To get a true overhead cost for when you do get past the start-up phase, your company should be paying you rent (but for tax purposes, only if you’ve allocated a room solely for soap making).

In this simple example, we’ll say renting a room is $200 (mortgage of $800 divided by 4). Next, you have your phone/internet bill, heating, electric, water, sewer, and garbage. Some indirect costs occur on a monthly basis, like rent, phone, and water. They may also include costs that vary from month to month, like marketing materials, design work, and website maintenance. That means the costs may fluctuate quite a bit.

Let’s not forget insurance! This is an essential you should have before starting any soap business. Learn more in the Insurance for Bath and Body Businesses article. On average, it runs about $20-40 per month. In this case, we’ve also factored in molds. If you prefer, you can factor the molds into the raw material cost (direct costs). But since they last longer than one use, we think it makes more sense to put them in here. Giving the extras category of $70 a month means you can replace things that break or wear out.

Rent - $200

Phone - $70

Water/sewer - $20

Electricity - $40

Insurance - $20

Extras (shelves, spoons, molds, postage, etc.) - $70

Total - $420

Direct Material Costs (Direct Costs)

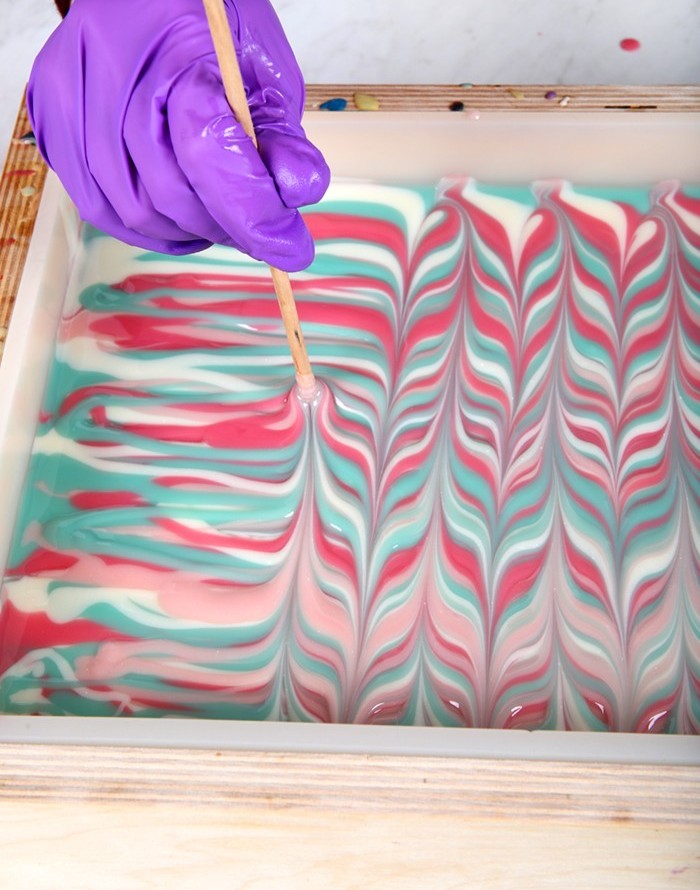

The direct cost of each batch varies because they have different ingredients. The examples below use an easy cold process recipe with three oils, one scent, and one color.

For this example, we’re using the 5 lb. Wood Mold, which holds 76 ounces of soap. You need 2.5 ounces of Energy Fragrance Oil for a light/medium scent. If we cut each batch into 3.8 ounce bars, we can get 20 bars from each batch.

Recipe in 5 lb. Mold - found using our Lye and Fragrance Calculators

Coconut Oil (33.3%) - 17.33 oz.

Olive Oil (33.3%) - 17.33 oz.

Palm Oil (33.3%) - 17.33 oz.

Sodium Hydroxide Lye - 7.6 oz.

Distilled Water - 17 oz.

Energy Fragrance Oil - 2.5 oz.

Sunset Orange Mica - 0.1 oz.

Total Yield - 76.5 oz.

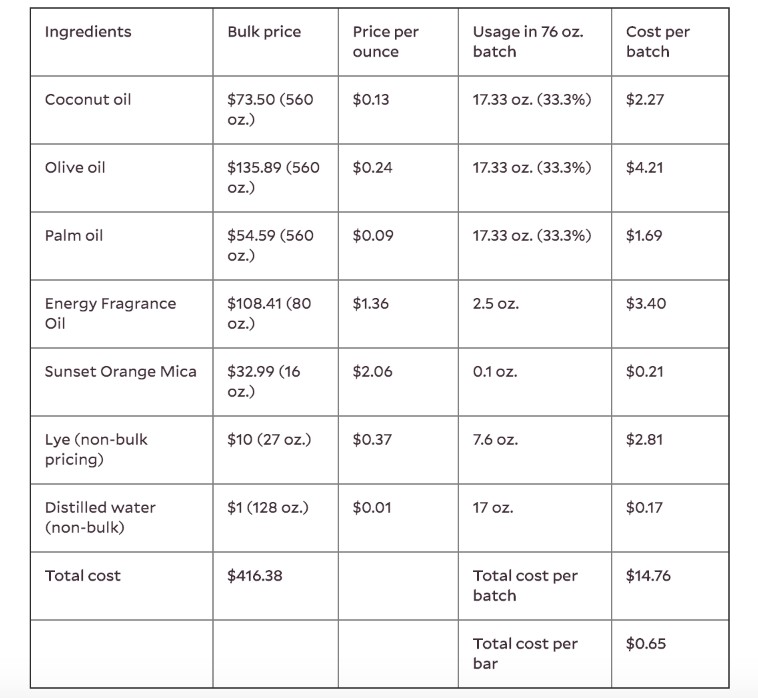

When you buy larger quantities of ingredients, the cost per pound/ounce is reduced. For example, 1 pound of olive oil is $6.49. This breaks down to about $0.41 per ounce. The price per pound reduces when you purchase 35 pounds of olive oil - it’s $135.89, or $0.24 per ounce. While this is more cost-effective in the long run, it does cost more upfront.

Let’s take a look at how the price per batch breaks down when you buy the ingredients in bulk sizes. The amount of colorant you need varies depending on personal preference. For this example, we estimate you need about 1 tsp. of Sunset Orange Mica, which weighs about 0.1 oz.

The chart also includes sodium hydroxide lye, which is not easily available in bulk sizes due to shipping/freight restrictions. The price of distilled water varies depending on your source. One gallon of distilled water at Walmart is $0.80, so we calculated an average of $1.

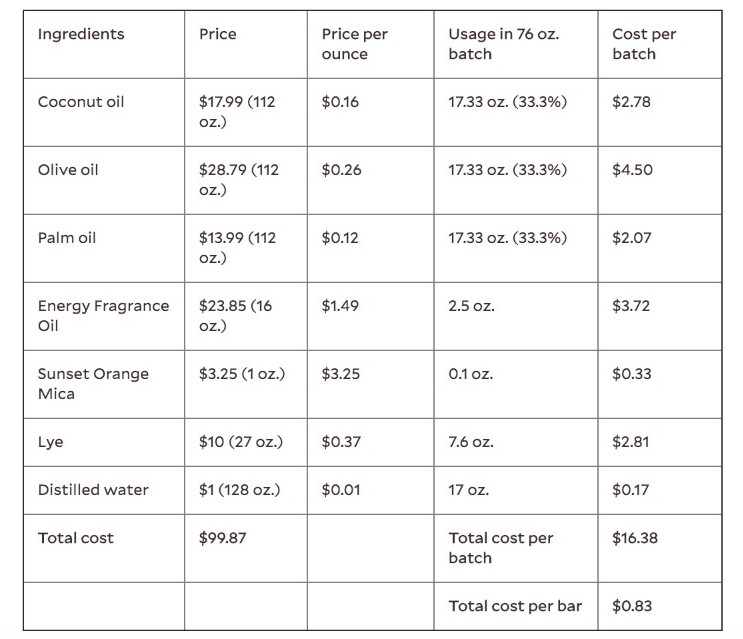

Now, let’s take a look at the cost per batch if you don't buy in bulk.

In the bulk example above, you have enough oils, colorant, and fragrance oil to make 32 whole batches of soap. This means you can produce 640 bars (32 batches x 20 bars = 640 bars). Keep in mind, you need to purchase more lye and distilled water to do so. It’s also important to remember that oils have a shelf life, they require storage space, and larger sizes may have increased shipping costs.

In the smaller example, you have enough supplies to create 6 batches of soap, or 120 bars. If you sell 120 bars a month, the indirect costs and labor costs increase the cost of each bar quite dramatically compared to producing and selling 640 bars.

In this example, the indirect costs this month are $420. If you sell 120 bars, that adds $3.50 to each bar ($420 divided by 120 bars = $3.50). If you produce 640 bars, that adds $0.65 per bar. Most small businesses produce an amount of soap that’s somewhere in between these amounts.

If you plan to sell large quantities of your products, buying in bulk is a great option. If you’re just starting out and only selling a few bars, smaller sizes may be the way to go. It’s up to you to decide.

Labor Costs

Labor also figures into this equation. How much do you want to pay yourself - $6 per hour, $15 per hour? For this example, we'll use $15 per hour and 30 minutes to prepare the raw materials (scoop, measure, and make up your recipe). The amount of time to make the soap varies, but let’s give ourselves 15 minutes to make the batch and 15 minutes to clean up. That’s a total of one hour per batch of soap. It creates 20 bars, which means the labor costs per bar are $0.75 ($15 an hour divided by 20 bars = $0.75).

Again, this is a simple example. Don’t forget to pay yourself when working on your website, packaging your bars, making sales calls, answering emails, etc.

Total Costs

Our direct material costs are $0.65 per bar when buying in bulk, the labor cost per bar is $0.75, and the indirect costs for the month are $420. If you sell all 640 bars, the indirect costs add $0.65 per bar of soap ($420 divided by 640 = $0.65).

Total Cost per Bar with Bulk Pricing

Direct Material Costs - $0.65

Indirect Costs - $0.65

Labor Costs - $0.75

Total - $2.05

Now let’s do the pricing for smaller batches. The indirect costs for the month are $420. If you sell all 120 bars, the indirect costs are $3.50 ($420 divided by 120 = $3.50).

Total Cost per Bar with Non-Bulk Pricing

Direct Material Costs - $0.83

Indirect Costs - $3.50

Labor Costs - $0.75

Total - $5.08

As you can see, selling 120 bars vs. 640 bars per month greatly affects your profit on each one because of the overhead.

For another example, let’s assume you purchased your ingredients using bulk prices. But you only produced and sold 360 bars of soap, which is 18 batches of the recipe above. You have plenty of ingredients leftover for next month. The indirect costs for the month stay the same ($420). If you created and sold 360 bars, your indirect costs would add on $1.17 ($420 divided by 360 = $1.17).

Total Cost per Bar with Bulk Pricing

Direct Material Costs - $0.69

Indirect Costs - $1.17

Labor Costs - $0.75

TOTAL - $2.61

Once you know how much you need to charge per bar to break even, you can decide how much to add onto the price to make a profit. But how do you find out what the final price should be? It's ultimately up to you. Here are some strategies you can use.

- The Multiplier Strategy: Multiplying your costs by a specific value to get your final price.

- The Percentage Strategy: Multiplying your costs by a percentage to get your final price.

- The Fixed Amount Strategy: Adding a fixed amount to every item to reach your price.

If you’re a business owner, you know the importance of carefully tracking your costs and profits. It’s definitely time consuming and tedious, but it’s worth it to ensure you’re on track. Be in control of your business - don’t let your finances surprise you.